UV curing is a technology that has revolutionized various industries by offering a fast, efficient, and environmentally friendly way to cure coatings, adhesives, and inks. This process utilizes ultraviolet light to initiate a photochemical reaction that leads to the rapid hardening or drying of a material. But what exactly makes UV curing so significant, and why is it increasingly being adopted across different sectors? Let’s explore the purpose of UV curing and its wide-ranging applications.

What is UV Curing?

UV curing is a photochemical process that uses ultraviolet light to cure or dry materials. The process involves exposing a specially formulated substance, such as a coating, adhesive, or ink, to UV light. This exposure triggers a chemical reaction that causes the material to harden or set almost instantaneously. Unlike traditional curing methods that rely on heat or air drying, UV curing offers several distinct advantages.

The Science Behind UV Curing

At the heart of UV curing is the use of photoinitiators, which are compounds that absorb UV light and break down into reactive species. These reactive species then initiate polymerization, a process where small molecules called monomers join together to form long chains or networks, resulting in a solid or hardened material. The rapid nature of this reaction is one of the key benefits of UV curing.

Benefits of UV Curing

The adoption of UV curing technology has been driven by its numerous benefits, which include speed, efficiency, and environmental advantages.

Rapid Processing

One of the primary benefits of UV curing is its speed. Traditional curing methods can take minutes to hours, whereas UV curing can complete the process in a matter of seconds. This rapid processing time increases production efficiency and throughput, making it ideal for high-volume manufacturing environments.

Energy Efficiency

UV curing is energy-efficient because it does not require high temperatures. Traditional curing methods often rely on ovens or other heating mechanisms that consume significant amounts of energy. In contrast, UV curing uses ultraviolet light, which significantly reduces energy consumption and operational costs.

Environmental Friendliness

UV curing is considered environmentally friendly because it reduces the emission of volatile organic compounds (VOCs). Many traditional coatings and adhesives release VOCs during the curing process, contributing to air pollution and posing health risks. UV-curable materials typically contain fewer solvents, resulting in lower VOC emissions and a safer working environment.

Improved Product Quality

The precise control offered by UV curing results in superior product quality. The process ensures uniform curing, reducing defects such as bubbles, blisters, or uneven surfaces. Additionally, UV-cured materials often exhibit enhanced properties, including better adhesion, hardness, and resistance to chemicals and abrasion.

Applications of UV Curing

The versatility of UV curing has led to its adoption across a wide range of industries. Its applications are diverse, from electronics and automotive to printing and healthcare.

Electronics

In the electronics industry, UV curing is used for encapsulating and protecting delicate components. The rapid curing time and high precision of the process make it ideal for applications such as conformal coatings on printed circuit boards (PCBs) and the assembly of microelectronics.

Automotive

The automotive industry benefits from UV curing in various ways, including the painting and coating of car parts. UV-curable coatings provide a durable, high-gloss finish that is resistant to scratches and environmental factors. This technology is also used in the bonding and sealing of automotive components.

Printing

UV curing has transformed the printing industry by enabling high-speed, high-quality printing. UV-curable inks dry instantly upon exposure to UV light, allowing for immediate handling and further processing. This technology is widely used in digital printing, screen printing, and offset printing, offering vibrant colors and excellent durability.

Healthcare

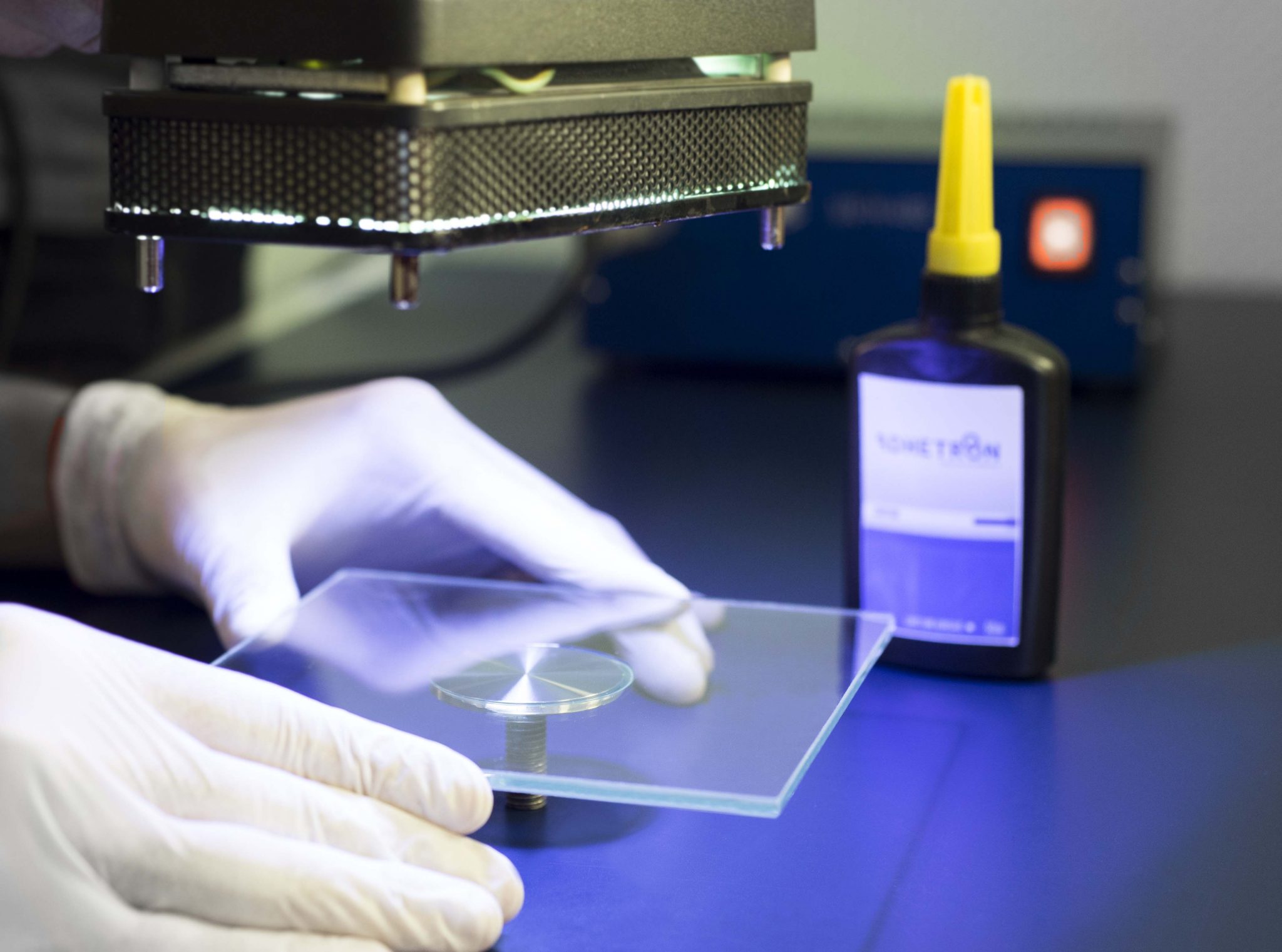

In healthcare, UV curing is employed in the production of medical devices and dental materials. The precision and speed of UV curing are crucial for manufacturing items such as catheters, syringes, and dental fillings. The biocompatibility and strength of UV-cured materials make them suitable for medical applications.

Manufacturing

UV curing is also prevalent in various manufacturing processes, including the production of optical lenses, fiber optics, and consumer electronics. Its ability to cure materials quickly and uniformly ensures high-quality, consistent results in mass production.

Future Trends in UV Curing

Advances in technology continue to push forward the evolution of UV curing, as research and development are undertaken with a view to broadening this technology’s features and areas of application.

Advancements in UV LED Technology

One significant trend is the development of UV LED technology, which offers several advantages over traditional mercury vapor lamps. UV LEDs are more energy-efficient, have a longer lifespan, and generate less heat. These benefits make them an attractive option for various UV curing applications, particularly in industries that require precision and environmental sustainability.

New Photoinitiators and Formulations

Research into new photoinitiators and UV-curable formulations is enhancing the performance and versatility of UV curing. These advancements aim to improve the curing depth, speed, and adhesion of UV-cured materials. Additionally, new formulations are being developed to expand the range of materials that can be cured using UV light, including more flexible and durable options.

Integration with Digital Manufacturing

Another promising trend is combining UV curing with digital manufacturing methods like 3D printing or additive manufacturing. Through UV curing, materials are bound together quickly and accurately during the 3D printing process which makes it possible to produce complex and very detailed parts using UV light. This collaboration between UV cured systems and digital production technologies has introduced new frontiers into various areas including prototyping; aerospace industry as well as bespoke production lines.

Conclusion

UV curing is a transformative technology that offers numerous benefits, including rapid processing, energy efficiency, environmental friendliness, and improved product quality. Its applications span a wide range of industries, from electronics and automotive to printing and healthcare. As advancements in UV LED technology, photoinitiators, and digital manufacturing continue to emerge, the potential of UV curing will only grow, further cementing its role as a critical tool in modern manufacturing and production processes. Understanding the purpose and benefits of UV curing can help industries harness its full potential, leading to more efficient, sustainable, and high-quality outcomes.